Camille's Stirling Engine Project

Tuesday, March 17, 2015

Problems and Final Engine

After finishing my engine, there were several issues that I had to address. For one, the music wire above the displacer was not dropping at regular intervals, so I had to straighten the wire to allow it to drop normally. I also had to smooth the balloon and epoxy the pvc elbow because air was escaping through gaps in the balloon and epoxy. Then I placed a counterweight on the disc to help it rotate, and finally the engine worked.

Here is the finished engine, which runs slowly, but does run.

Tuesday, February 24, 2015

Attaching the PVC Elbow

We attached the PVC elbow to the rest of the engine using a quick-drying epoxy. I found that it was easier to attach the elbow when I put epoxy both on the can and on the elbow itself.

Thursday, February 19, 2015

Make a Drinking Straw Riser around the Pushrod and Pinhole

I held down the straw firmly as I put the apoxy on, but it was difficult to reach the back side of the straw. In order to create the seal, I allowed one side to dry more or less before sealing the other side, so that I reduced the possibility of shifting the straw around.

Crankshaft

I had to outline my crankshaft diagram and then form my crankshaft based on this diagram. I found that it helped when shaping to make sure that my wire was straight as I bent it.

Wednesday, February 18, 2015

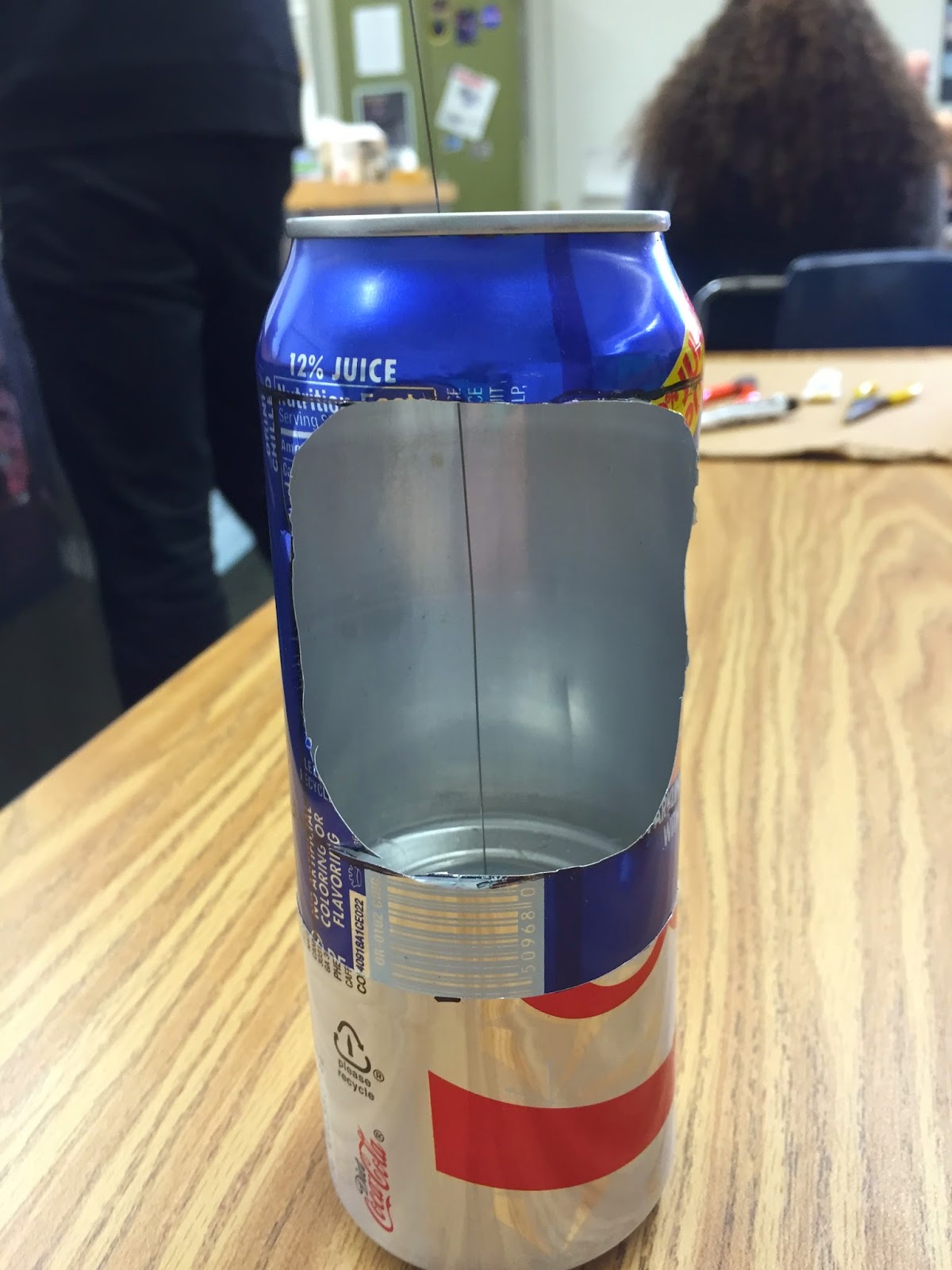

Making the Displacer Pushrod & Creating the Pressure Chamber

We used music wire bent at a 90º angle and a quick drying apoxy to create the pushrod. We then placed the displacer and pushrod into the bottom chamber and stuck the wire through a hole in the upper part of the pressure chamber. We pushed the two halves together, and then cut a hole out of the upper pressure chamber, which was made easier by using smaller angled scissors.

Measuring & Cutting Bottom Can of Pressure Chamber

After having measured and marked two cans, I used small scissors to cut along the line creating the bottom can of the pressure chamber. Keeping the line stable and the aluminum from going jagged was hard, but it made it easier to hold the scissors horizontally to the can.

Displacer

We created the displacer, which was kind of hard to shape because of the fragility of the foam. I found that it helped to rub the foam into shape rather than to press or roll it.

Subscribe to:

Comments (Atom)